We follow a meticulous, multi-step process to ensure every piece of furniture meets our exacting standards:

Astho Spaces takes pride in its robust manufacturing infrastructure and expertise:

Ensuring precision and efficiency in all production stages.

Delivering finishes that are both stunning and durable.

Minimizing environmental impact through energy-efficient processes, waste reduction and the use of eco-friendly materials.

Combining skill and technology to create versatile designs.

Offering tailored solutions with premium materials and exceptional craftsmanship.

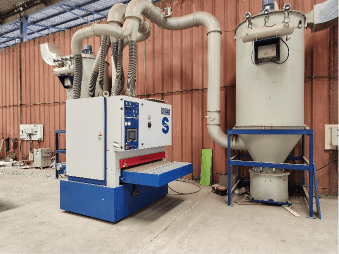

State-of-the-art veneer manufacturing facility equipped with cutting-edge technology, our veneer manufacturing facility boasts:-

Our commitment to quality, innovation and efficiency ensures exceptional veneer products that meet the highest standards.

Astho Spaces takes pride in its robust manufacturing infrastructure and expertise:

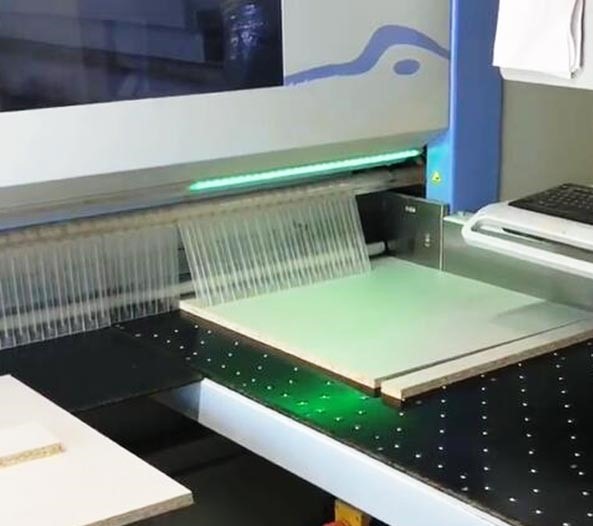

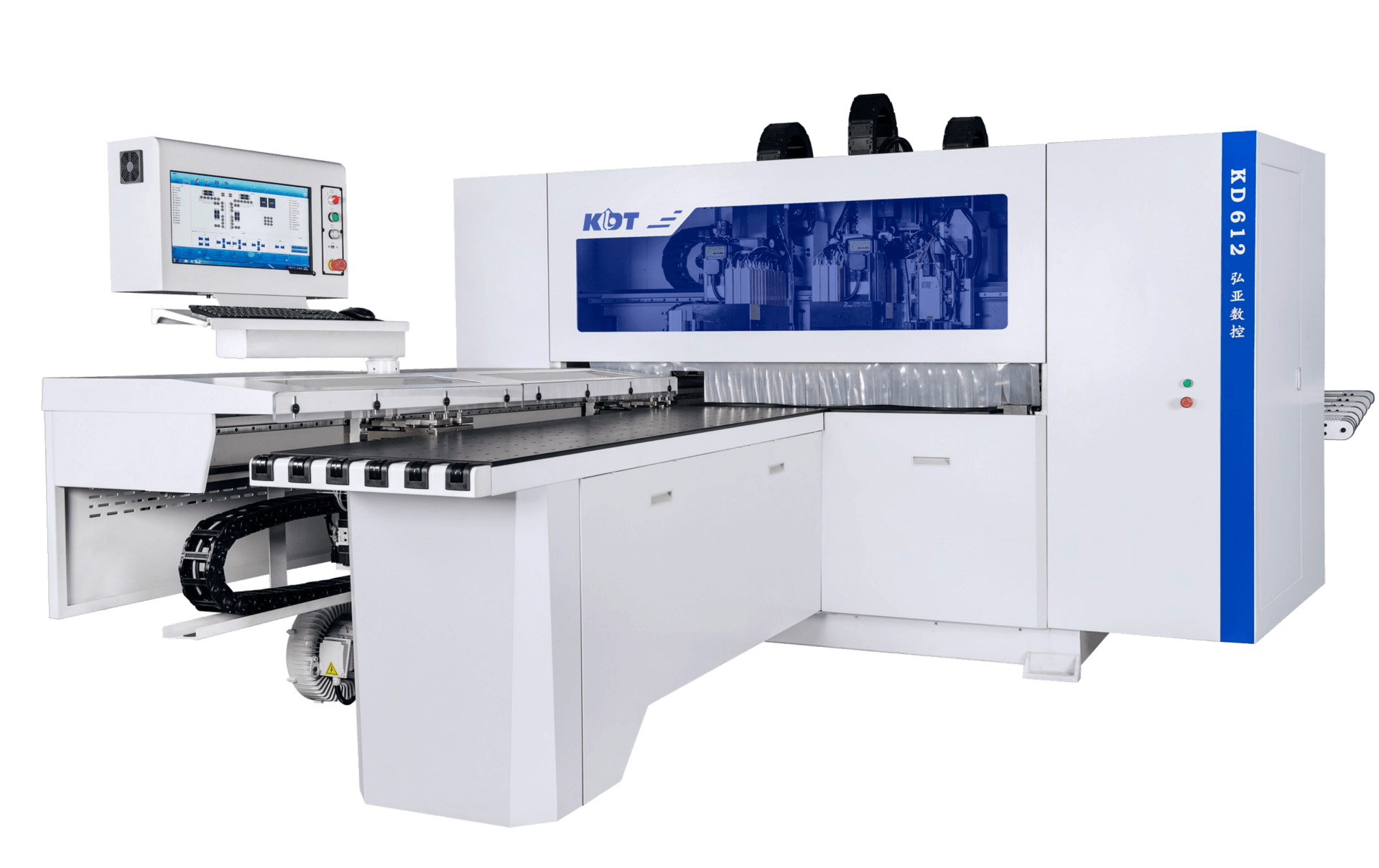

The fully automatic CNC beam saw is a key asset in our best office furniture manufacturing process, designed for precision cutting and panel sizing. This advanced machine ensures high performance, versatility, and unmatched accuracy with maximum efficiency.

Applications

The CNC beam saw is capable of processing a wide range of materials, including:

Benefits:

The CNC beam saw is capable of processing a wide range of materials, including:

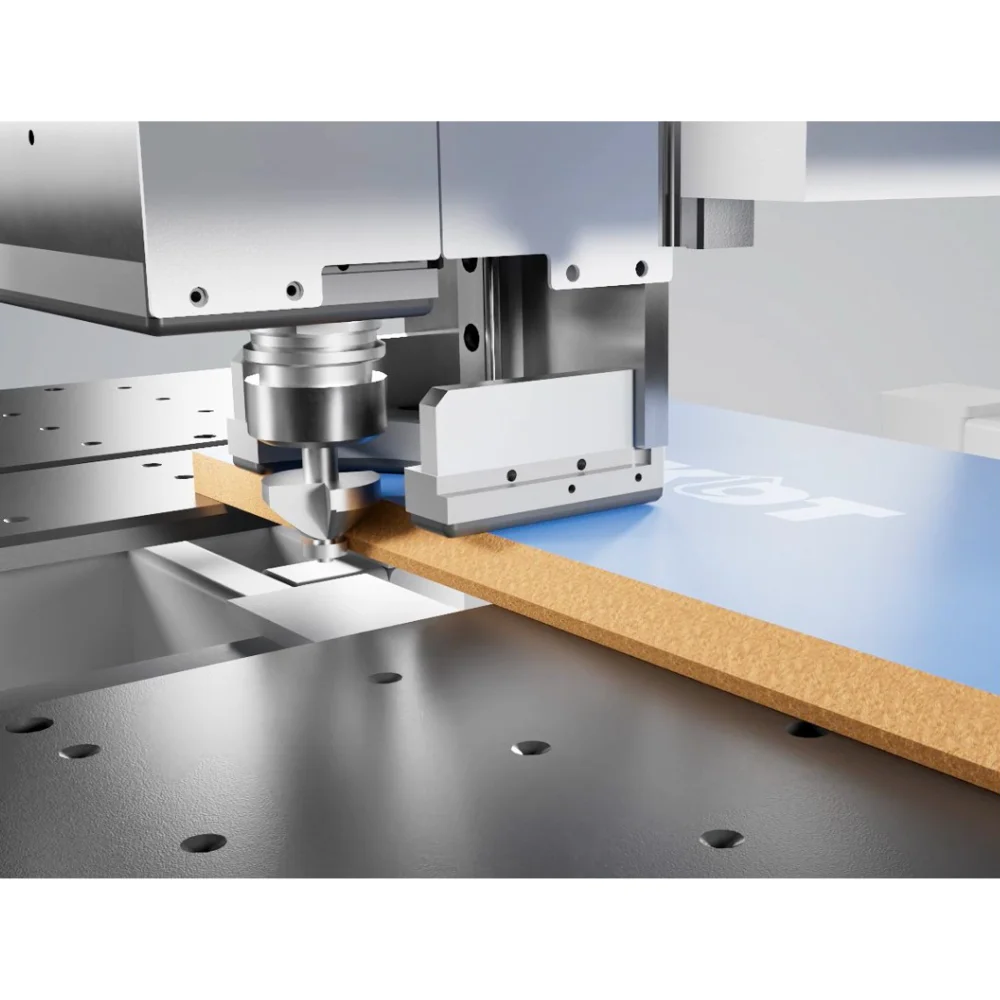

The Computer Numerical Control (CNC) router is a versatile and precise machine essential for best office furniture manufacturing. It plays a pivotal role in shaping, cutting, and detailing furniture components. Controlled by advanced programming, it ensures precision, repeatability, and efficiency in every operation.

Applications:

The CNC router is used for a variety of tasks, including:

Industries and Products:

This machine supports the production of:

Benefits:

This machine supports the production of:

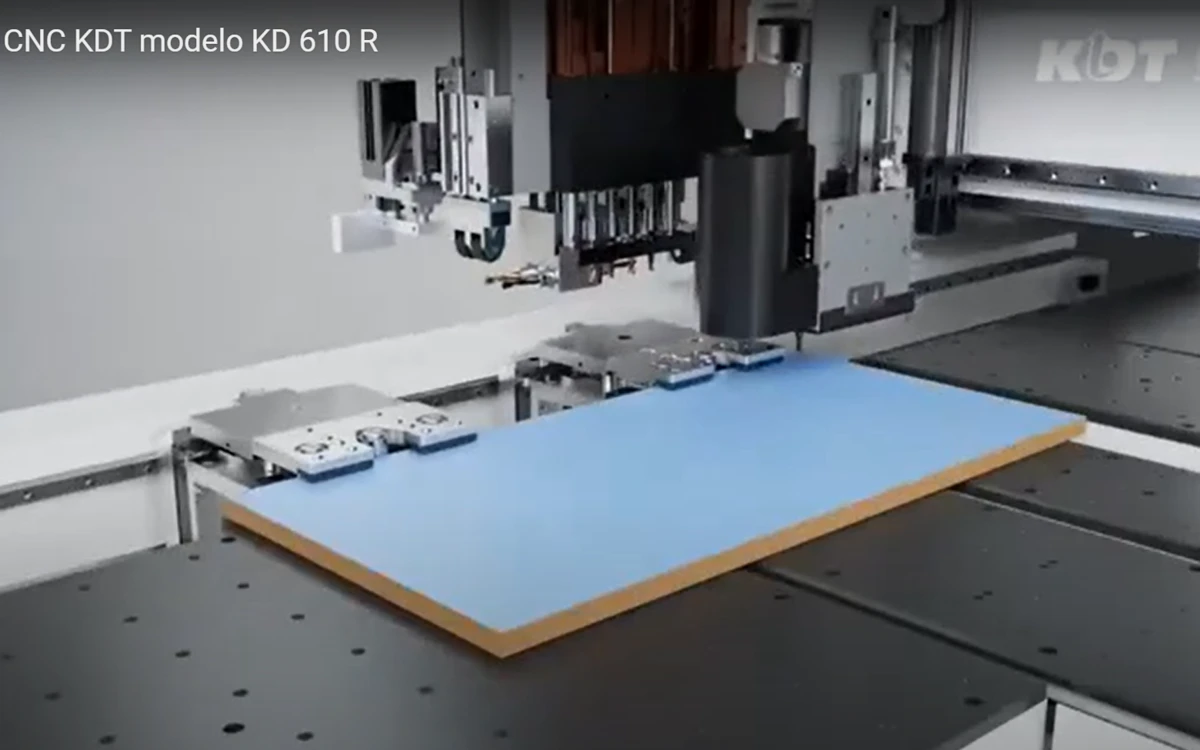

The CNC drill machine is a high-precision tool designed for creating perfectly oriented holes in furniture components. Essential for the best office furniture manufacturing, its advanced features ensure accuracy and efficiency in the production process.

Capabilities:

This machine ensures that every hole is accurately aligned and positioned, enhancing the structural integrity and aesthetic appeal of the final product in the best office furniture manufacturing.

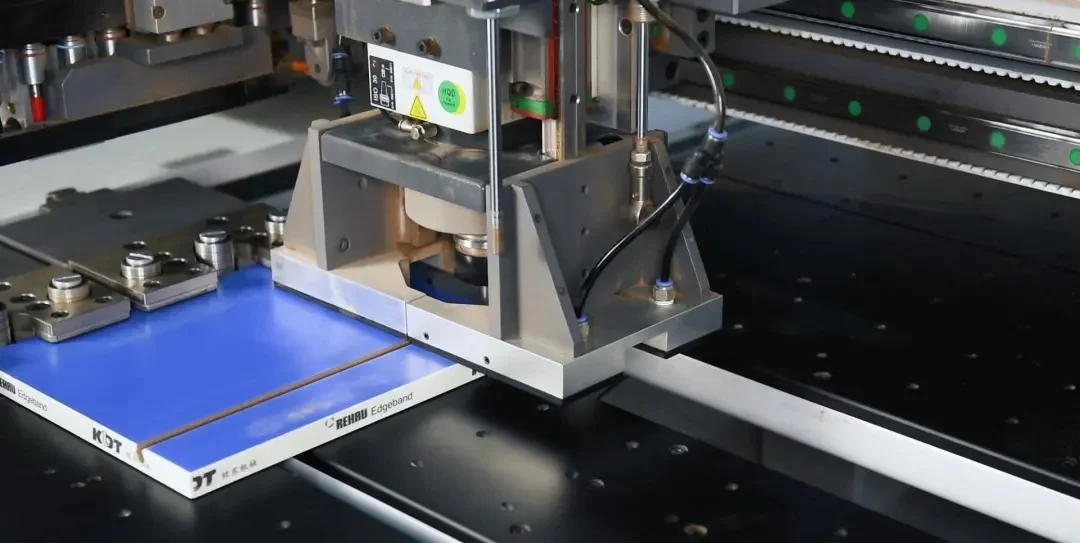

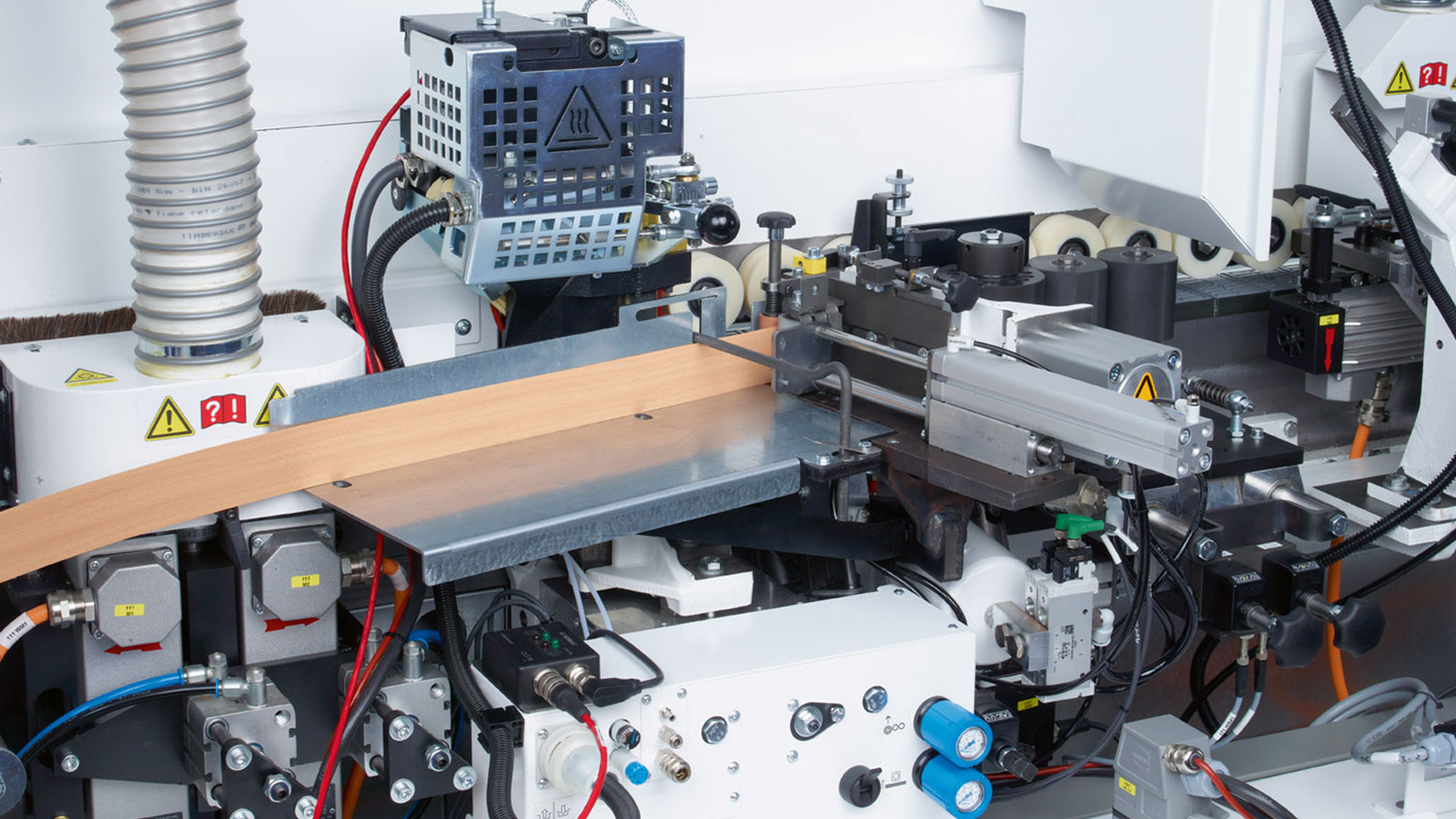

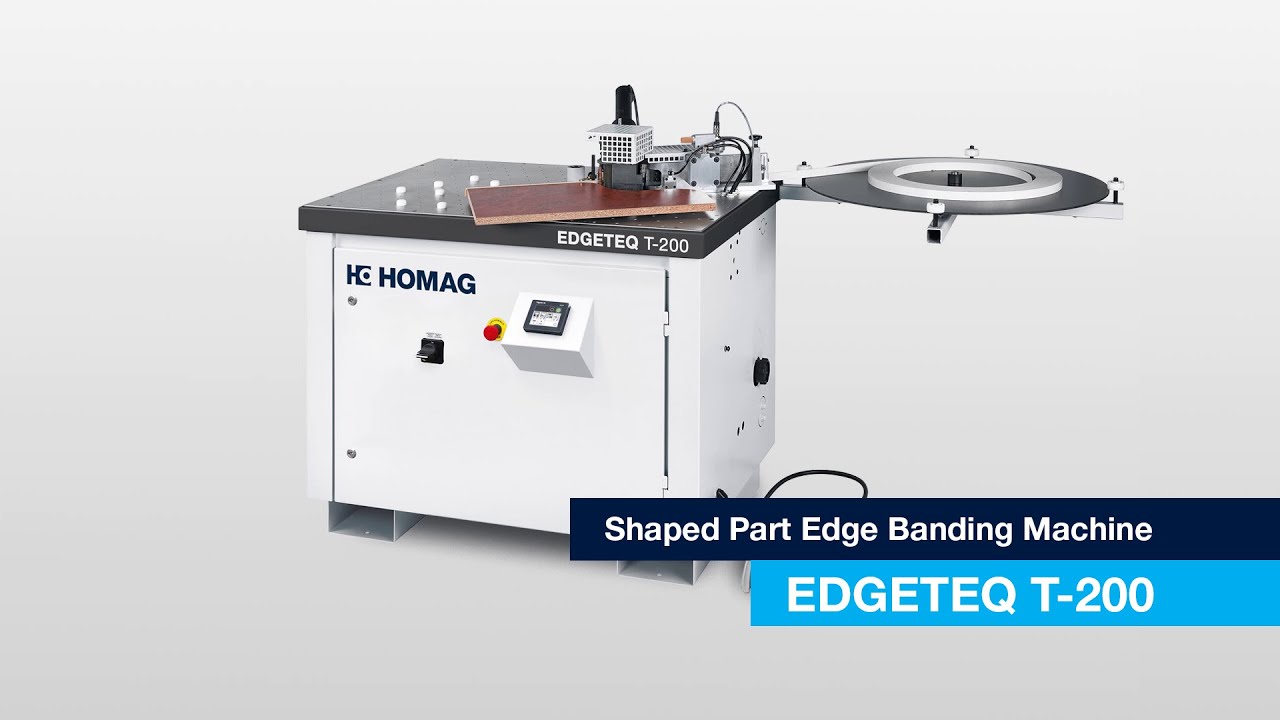

The Edge Bander is a fully automated machine dedicated to applying edge banding on straight edges. Essential for the best office furniture manufacturing, it enhances the longevity and aesthetics of furniture components, giving them a polished and professional finish.

Key Capabilities:

With a production speed of 16 to 20 meters per minute, the Edge Bander ensures high-volume production without compromising quality, making it an essential tool for best office furniture manufacturing.

Edge Banding Materials

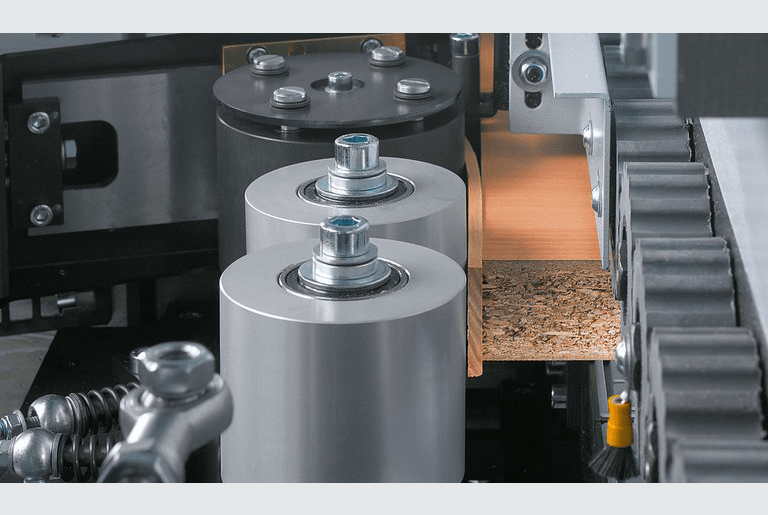

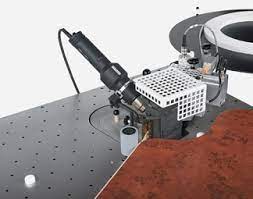

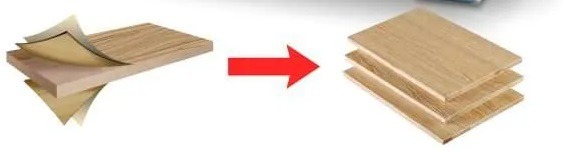

Edge banding is a critical process in best office furniture manufacturing, and our Curvilinear Edge Banding Machine enables seamless finishes on intricate shapes and curved edges.

Purpose of Edge Banding:

Application Process:

Materials Used for Edge Banding:

We offer a range of edge banding materials to suit different applications, including:

Hot Press machine is used for Mica and Veneer Pressing. Electric Hot Press is most suitable and environment-friendly Machine. Best office furniture manufacturing relies on Hot Press Machines with an advanced European Hydraulic System, PLC control, and Touch Screen HMI. Uniform heating is achieved through Electrical Heating with high-quality Resistance Heaters. Hot Press is most suitable for Panel Processing Industries & Modular Furniture Industries.

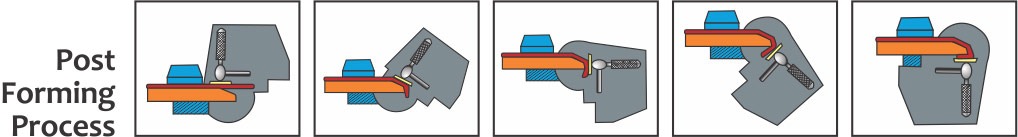

The term ‘post-forming’ in best office furniture manufacturing refers to the bending process applied to specially developed grades of laminate. These laminates retain all the properties of standard high-pressure laminates while allowing for seamless cylindrical concave or convex curves.

At Astho Spaces, our best office furniture manufacturing excellence is rooted in a passion for quality. From sourcing premium materials to utilizing state-of-the-art machinery, we prioritize durability, aesthetics, and innovation in every product. Whether you’re seeking cost-effective office furniture or bespoke high-end solutions, our unwavering dedication ensures that every piece exceeds expectations.

What truly sets Astho Spaces apart is our holistic approach to customer satisfaction. From best office furniture manufacturing to delivery and expert installation, we guide you through every phase, ensuring a seamless, stress-free experience. With advanced manufacturing capabilities, sustainable practices, and a customer-first philosophy, Astho Spaces is proud to be your trusted partner in creating furniture that transforms spaces and enhances lives.

At Astho Spaces, we’re driven by a singular passion: to revolutionize the way people work, live, learn and interact. Since 2015, we’ve been transforming interior spaces into vibrant hubs of creativity well-being, and productivity.